Introduction: In a large number of industrial and test equipment applications, high pressure gas is an important part of the test process. The gas booster station produced by our company mainly pressurizes the gas in the steel cylinder ≤15MPa to the pressure vessel 70MPa to meet the high pressure requirements of instruments and equipment. And refer to the domestic and foreign standards, comprehensive domestic and foreign advanced technology, perfect process, excellent manufacturing quality, fully save energy.

Equipment features: The main parts of the system adopt the brand of SITEKE Company to ensure the quality, safety and reliability of the equipment; Safe and convenient operation, with high voltage test performance. The system has high efficiency during pressurization test. Reduce the labor intensity of workers and increase the safety of staff.

Technical part: Connect the power air source port of the gas booster station with the air source of the air compressor, and connect the booster air source at the same time. Open the drive air stop valve at the gas booster station. Then open the high pressure stop valve, the system begins to pre-inflate and pressurize the workpiece, after the pressure is completed, close the high pressure stop valve, the system begins to maintain pressure, after the pressure is maintained, open the high pressure unloading valve for pressure relief, and then close all the stop valves. Use a special operator to adjust the reducing valve on the drive loop. After setting, do not adjust it randomly. (Press down the handle of the reducing valve, and the regulating device is locked)

System maintenance and maintenance:

1. After each test, clean the inside and outside of the equipment, and pay attention to the sealing and dust-proof of the air inlet and high pressure outlet.

2, clean air source without water, no solid granular impurities.

3. Remove the water in the filter element regularly, and replace the filter element regularly according to the use.

4, equipment transportation should avoid vibration, to prevent damage to the digital display table.

5. If the equipment is idle for a long time, it is necessary to open the equipment regularly for several times to avoid the aging of its internal sealing ring.

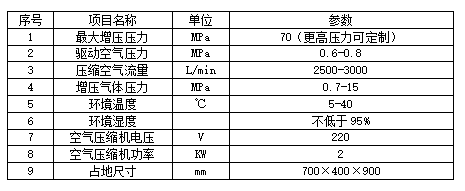

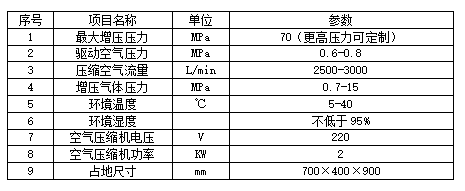

Specification parameter