I. Overview:

Fracturing fluid friction tester is used to study the shear rate of solid and liquid fluid flow in the laboratory test pipeline after adding a certain drag reduction fluid, which is the same as the shear rate of liquid flow in the pipeline during field construction. Thus used to simulate the flow state of liquid field construction, to determine the pipeline friction, so as to determine the advantages and disadvantages of drag reducer.

By measuring the friction of clear water and different fracturing fluids at different shear rates through the pipeline, the ratio β of clear water friction and different fracturing fluids friction at different shear rates was obtained.

β= frac fluid friction/water friction

At the same time, the corresponding graph can be drawn according to the computer acquisition system.

In order to evaluate the frictional reduction performance of fracturing fluid, further understand the change law of frictional resistance of different fracturing fluids, different discharge rates and different well depths, and provide a basis for fracturing fluid optimization and fracturing optimization,

The pipeline friction meter has the following functions:

1. Can correspond to simulated site construction displacement;

2, the experimental liquid including water, base liquid, reducing resistance agent, can be carried out under the condition of high liquid viscosity experiment;

3. Base liquid tank and cross-linked liquid storage tank are equipped respectively, and the flow rate of base liquid and cross-linked liquid can be adjusted as required to achieve the designed base cross ratio;

4. The equipment design scheme adopts circulating lines and pipelines of various specifications to simulate the flow of fracturing fluid in pipelines on site;

Ii. Characteristics:

1. Use the closed cycle flow system, continuous test;

2. Multiple test results can be obtained in one test, saving time and reducing the requirement of test liquid;

3. The test liquid is circulated in a straight line in the pipeline, and the liquid structure will not be damaged;

4. The over-temperature and over-pressure alarm and stop device are set on the test pipe to ensure the safety of the test;

5. Parameter measurement and control using high-precision differential pressure transmitter, pressure sensor, electronic flowmeter, precision temperature control instrument, etc., to ensure reliable test results;

Three, function:

1, the determination of different displacement of water friction, in order to compare with the test liquid friction, to provide a basis for construction design.

2, the determination of oil test liquid friction, evaluation of oil resistance reducing agent.

3, data acquisition and processing are automatically completed by the computer, easy to operate.

Four, the main structure:

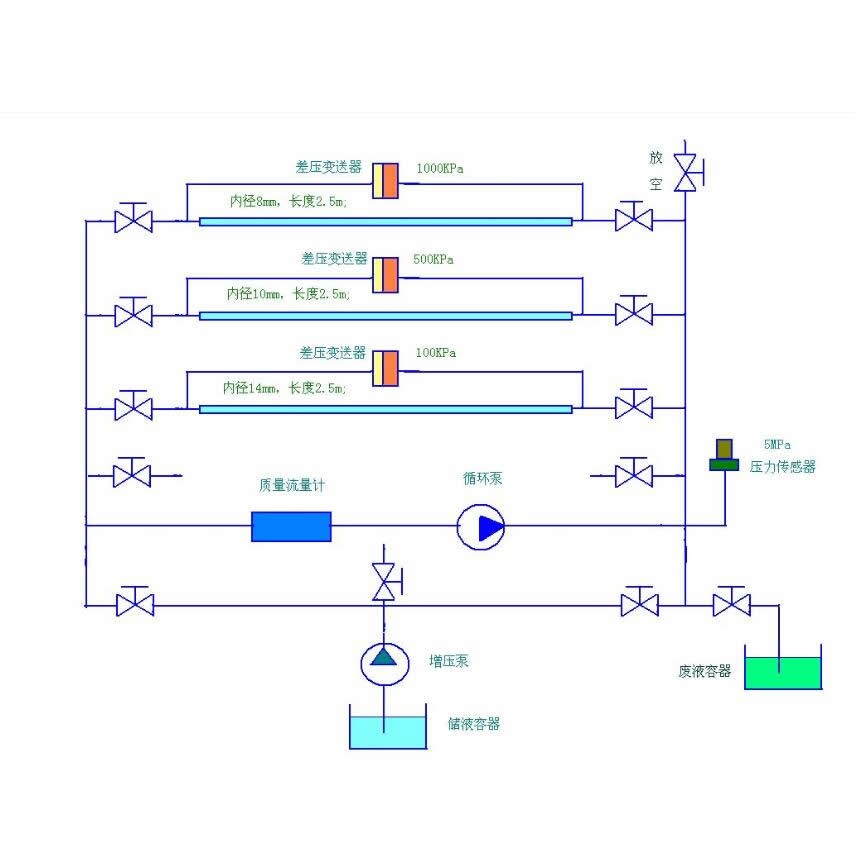

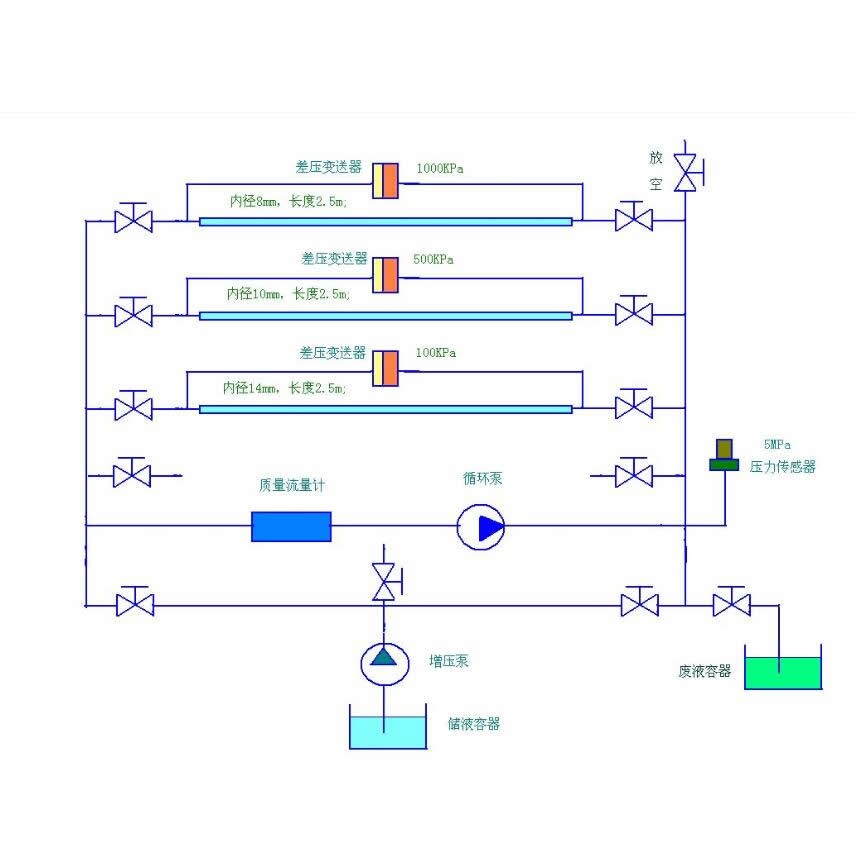

The device is mainly composed of injection system, simulation system, constant temperature system, pressure measurement system, differential pressure measurement system, flow meter, pressure protection system, data acquisition and processing system.

V. Process diagram

Specification parameters:

1.Maximum operating temperature: ≤140℃

2.Working pressure: ≤5Mpa

3.Test differential pressure range:0-100.,500,1000Kpa

4.测试粘度: 1.~2x106MPa.s

5.Pipeline:(1)Inside diameter8mm, length2.5 m; (2)Inside diameter10mm,长度2.5 m; (3)Inside diameter14mm,长度2.5 m; (4)Inside diameter8mm,长度8mcoil

6.Injection flow rate:24L/min-200L/min

7.Power supply:380V8KW